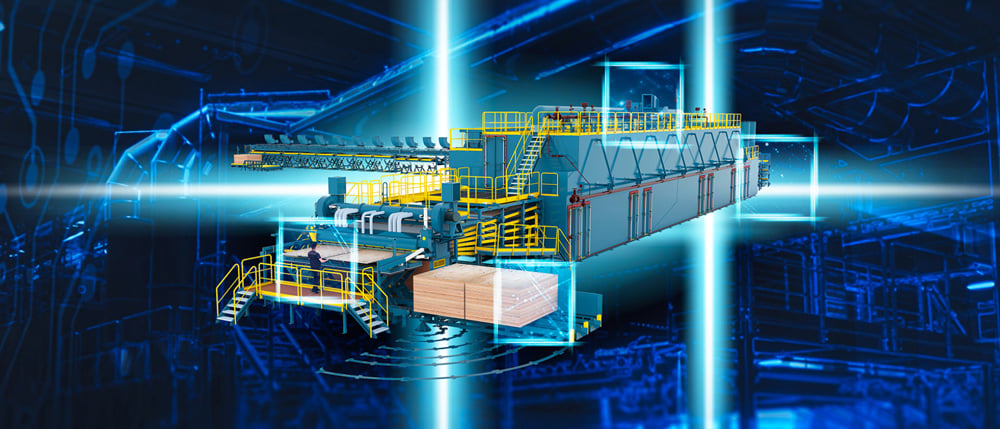

Future-proof your veneer drying with Raute

Veneer drying is the key to premium products.

Veneer drying is one of the most important stages in the production of wood-based panels, such as plywood and LVL (laminated veneer lumber).

Veneer quality improves notably with a modern drying process. With the right conditions and Raute equipment, you can also avoid excess energy consumption, raw material usage and waste.

Make your manufacturing more economical, more sustainable and more reliable.

Whatever your needs are, consider them met.

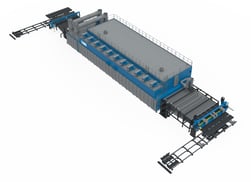

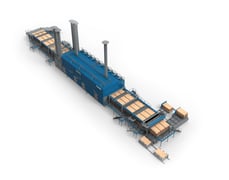

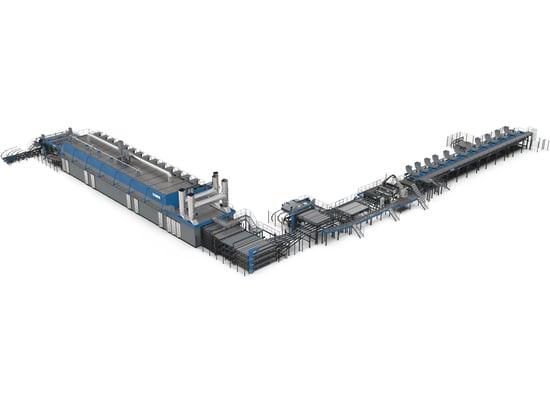

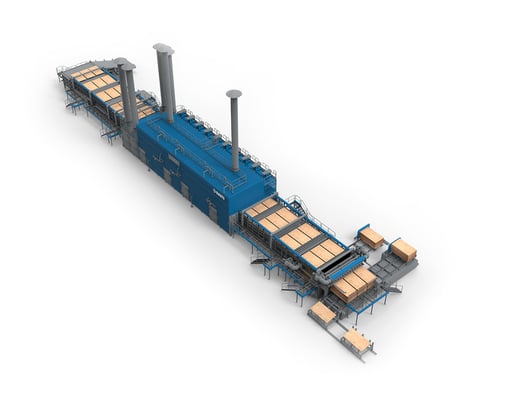

Raute has a range of veneer drying lines, each one fitting a variety of needs.

Download our whitepaper on the veneer drying process

Our six-page whitepaper documents the fundamental factors and physics of veneer drying. What the key to quality is and what the most optimal drying conditions are.

Read our whitepaper by Veneer drying technology expert Toni Antikainen.

H2 title for the content

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut velit justo, consectetur sed sodales eu, bibendum in quam. Aenean lacinia pretium elit vitae blandit. Quisque quis nibh ex. Curabitur aliquet, magna non suscipit dapibus, sem elit pulvinar mi, vitae condimentum mi tellus vel ante. Quisque ultricies laoreet ultricies.

- Quisque eget ligula eget urna efficitur ullamcorper.

- Nulla quis nisl et quam varius condimentum a quis lectus.

- Nam dictum sollicitudin posuere.

- Integer sit amet magna sem.

- Nunc eget auctor ligula, eget tempus diam.

Proin maximus dapibus purus sit amet finibus. Curabitur maximus tortor libero, ac consectetur velit venenatis nec.

Why and how should you dry veneer?

Technology Manager, Raute

Read more about the dos and don’ts of veneer drying, what drying is for and what it entails in this article by Raute’s expert in industrial engineering Jarkko Kaislaoja.

Drying technology and the process

DRYING THE VENEER QUICKLY AT LOW COST

KEEPING THE VENEERS FLAT AND SPLIT-FREE

MAINTAINING A UNIFORM MOISTURE LEVEL FOR GLUEING

Raute’s technology is designed for challenges and delivers on all points.

In veneer drying, moisture is forced to evaporate from the wood veneer sheets by heating in a modern veneer dryer or drying machine. It is a challenging process since the moisture variation in the wet veneer is very large and the final moisture level after drying should be very low.

.png?width=303&name=veneer-drying-line-R7+(2).png)

-(1)-1.png?width=301&height=170&name=veneer-drying-line-R7+(3)-(1)-1.png)