Raute MillSIGHTS

Improve your production by utilizing intelligent production data

Gain comprehensive data from essential elements in production

Raute MillSIGHTS is a revolutionary data hub Management Information System (MIS) for wood processing industries, especially for veneer, plywood, and LVL producers. MillSIGHTS software collects comprehensive data from the essential elements in production.

Real-time notifications

Key personnel receive notifications in real time if a production line is running inefficiently.

Comprehensive data gathering

The MillSIGHTS system gathers data from various production phases so you have as much information available as possible.

True insight

data

The MillSIGHTS system is built inside production line controls. This provides a real insight into conditions within the process and the production environment.

Dynamic data reporting

Hourly or annually, you will have the reports at your fingertips in the same amount of time. Dynamic filtering lets you filter the data to the report to match the point-of-view you are interested in.

*MillSIGHTS can also be used in non-Raute line solutions.

Download the brochure: Raute MillSIGHTS — The Key Features

Raute MillSIGHTS is a revolutionary Management Information System that gives you comprehensive data from essential elements of your veneer, plywood, and LVL production. The data produced by the analyzers is an important part of the overall data collection.

With MillSIGHTS you can improve your production efficiency and profit. Check it out!

See MillSIGHTS in action!

Play the video to see the software in action and learn how it can benefit your production.

What our

customers think?

The real-time data flow from machines allows the necessary information monitoring and collection for production development. Meanwhile catching performance trends enables us to deduce the necessity of immediate maintenance actions to keep production efficiency high. This data exchange meets the Industry 4.0 requirements and makes the data available for more conscious and precise production management.

Gino Ceresara, Engineering Manager at Panguaneta SPA

Reference: from major production challenges to increaced efficiency

The story about how a plywood mill producing

50 000 m³ of high-quality veneer annually overcame major production challenges and bottlenecks with Raute’s solutions and increased their production efficiency at the same time. Download and read the whole story now!

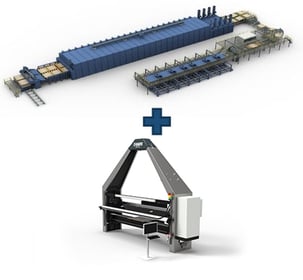

Analyzers 💙 MillSIGHTS

From basic production to intelligent data-based production.

Whether you want to start upgrading your production from the very start or you already have some knowledge about intelligent data-based production, we got you covered!

Step 1

Basic production