Ultimate recovery and quality with Raute’s R7 analyzers for veneer peeling and drying lines

Analyzers for peeling and drying are key elements in modern veneer grading. Jump right in and learn more about how you can streamline your production and especially veneer production recovery and quality.

Two crucial phases: peeling and drying

In veneer production, there are two crucial phases where you can improve the product quality and overall production efficiency – veneer peeling and drying. Veneer peeling is an important phase of veneer, plywood, and LVL production. The advanced R7 analyzers for veneer peeling line significantly improve process efficiency, veneer quality, and raw material utilization rate. In veneer drying, it is crucial to analyze and grade the veneer sheets for the following phases. The veneer drying line equipped with R7 series analyzers takes your production to a whole new level.

On this page, you will find a comprehensive package of knowledge about Raute’s R7 analyzers for peeling and drying and how they bring efficiency to your production. Check out the individual production line brochures and the reference story below.

Maximum raw material utilization rate

The data-driven knowledge enables the maximization of the raw material utilization rate. The best profit comes from minimum raw material waste and optimally clipped sheets to match the needs of subsequent processes.

Optimized clipping width

Each veneer sheet is clipped to an optimized width according to the drying shrinkage estimation. Minimized dry veneer width deviation. Less composable – More full-size veneer.

Maximum raw-material supply

Data-driven knowledge enables you to maximize raw material usage. The best profit comes from minimum raw material waste and optimally cut sheets for the following process. The optimization is easy to carry out with simulations based on the data from the analyzers.

Download the brochure: The key benefits of Raute’s R7 analyzers for veneer peeling line

Gain more knowledge about the peeling line analyzers and how you can improve your production using them. From the brochure, you will discover more benefits, and how you can increase your production efficiency through accurate grading. The brochure covers how this investment means profit.

Accurate visual grading

The precise visual analyzer provides high accuracy veneer grading by combining high-resolution defect detection with an advanced grading solution. Reduced reject ration and improved productivity in the following process phases are achieved with accurate visual grading.

More drying capacity with precise moisture grading

Low-end moisture sorting solutions need a wider range of margins to compensate for inaccuracy in moisture grading which leads to long drying times and extensive over drying of the veneer. Minimized margins with accurate R7 analyzers lead to shorter drying time and higher average moisture content of the veneer.

Advanced veneer strength grading

Grading decision based on a combination of strength, visual, and moisture properties results in the best outcome with the highest precision. Resulting in improved strength grading distribution giving more value for the raw material.

Download the brochure: The key benefits of Raute’s R7 analyzers for veneer drying line

Gain more knowledge about drying line analyzers and how you can improve your production using them. From the brochure, you will find more benefits and statements about why you should consider this investment. The brochure covers how data-based production is efficient and how you get rid of relying just on “gut feeling” in veneer grading and drying.

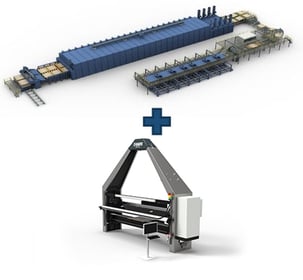

Maximize your benefits by combining analyzers with intelligent Raute MillSIGHTS

Whether you want to start upgrading your production from the very start or you already have some knowledge about intelligent data-based production, we got you covered! Raute MillSIGHTS is a revolutionary Management Information System that gives you comprehensive data from the essential elements of your veneer, plywood, and LVL production.

Step 1

Basic production

Reference: from major production challenges to increaced efficiency

The story about how a plywood mill producing

50 000 m³ of high-quality veneer annually overcame major production challenges and bottlenecks with Raute’s solutions and increased their production efficiency at the same time. Download and read the whole story now!